All from one source

All key elements of the value chain are located in-house: simulation, development, testing, metrology, prototyping and toolmaking as well as production and supply chain management.

Research & Development

Annually, we invest around ten percent of our revenue in research and development, which also includes the latest technologies, state-of-the-art infrastructure, and the continuous training of our employees. In total, about a quarter of our workforce is assigned to this area. The core areas of R&D include technology, products, and processes.

Actuation development

From an innovative concept idea through the verification sample to series production, our product and process engineers, simulation and test engineers, prototype builders and cutting machine operators work closely together to develop solutions for new vehicles and mobility concepts.

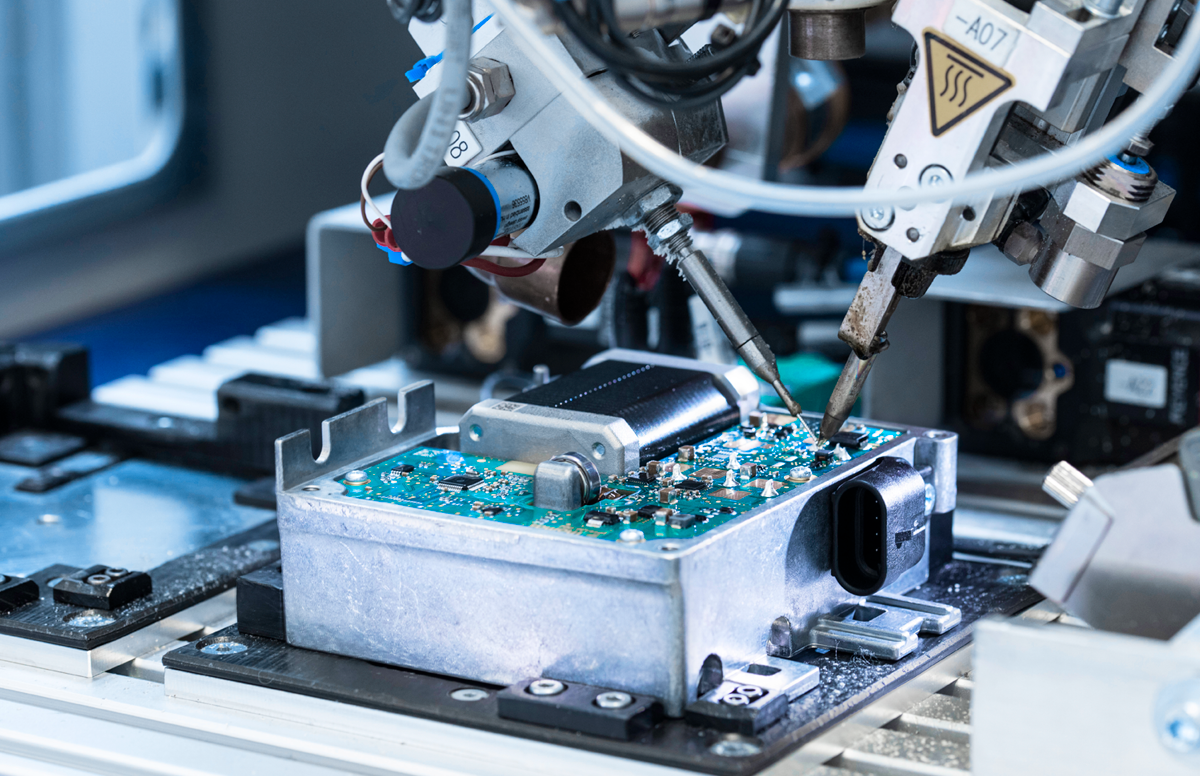

Electronics

Rethinking systems - this ability forms the basis of all innovation and progress. Our formula to achieving this: "Sense. Think. Act." (STA). Our Electronic Service Unit is not just about new inventions. Above all, it is about taking an all-embracing view of existing systems and equipping these systems with new sensor technology, software, and electronics – to an extent that has never been seen before.

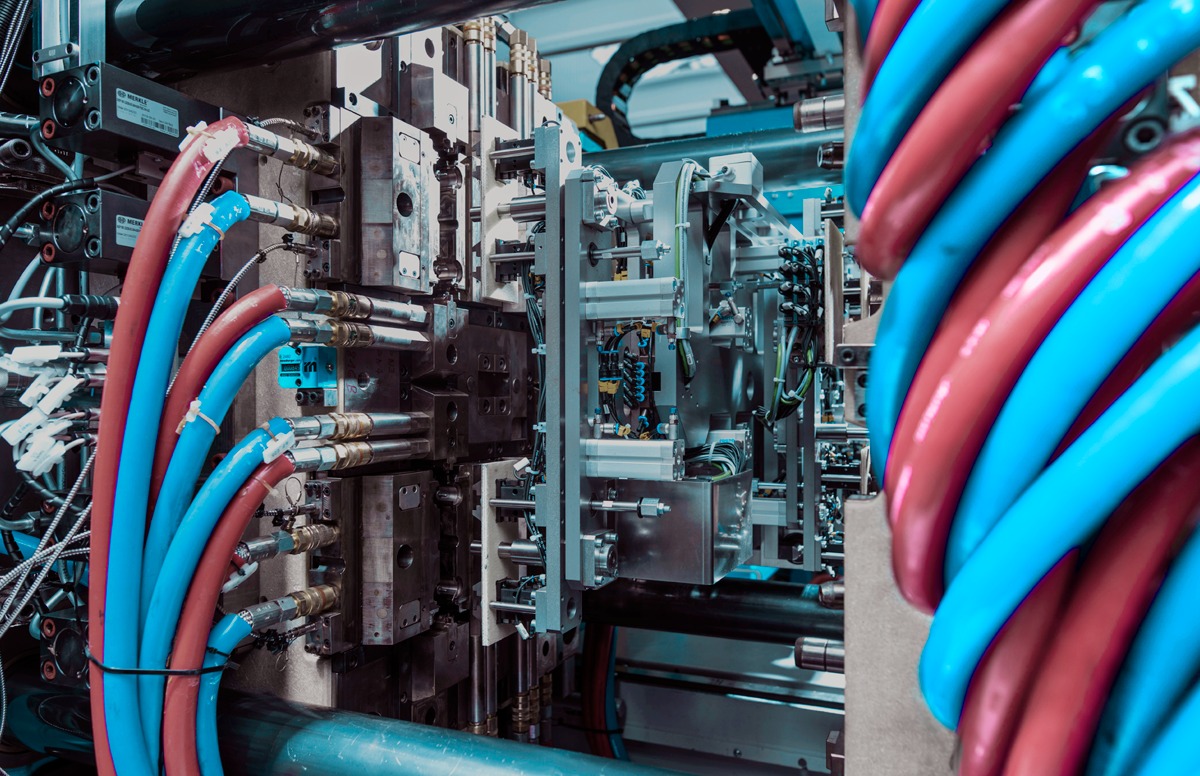

Plastics technology

Plastics technology is a fundamental building block for streamlined production at Thomas. Here, highly complex plastic components, electronic hardware, and sensor technology as well as individual metal components are overmolded to form functional groups. Thanks to our fully automated handling systems, including full inspection capabilities, all products are guaranteed to meet the exacting quality standards of our customers.

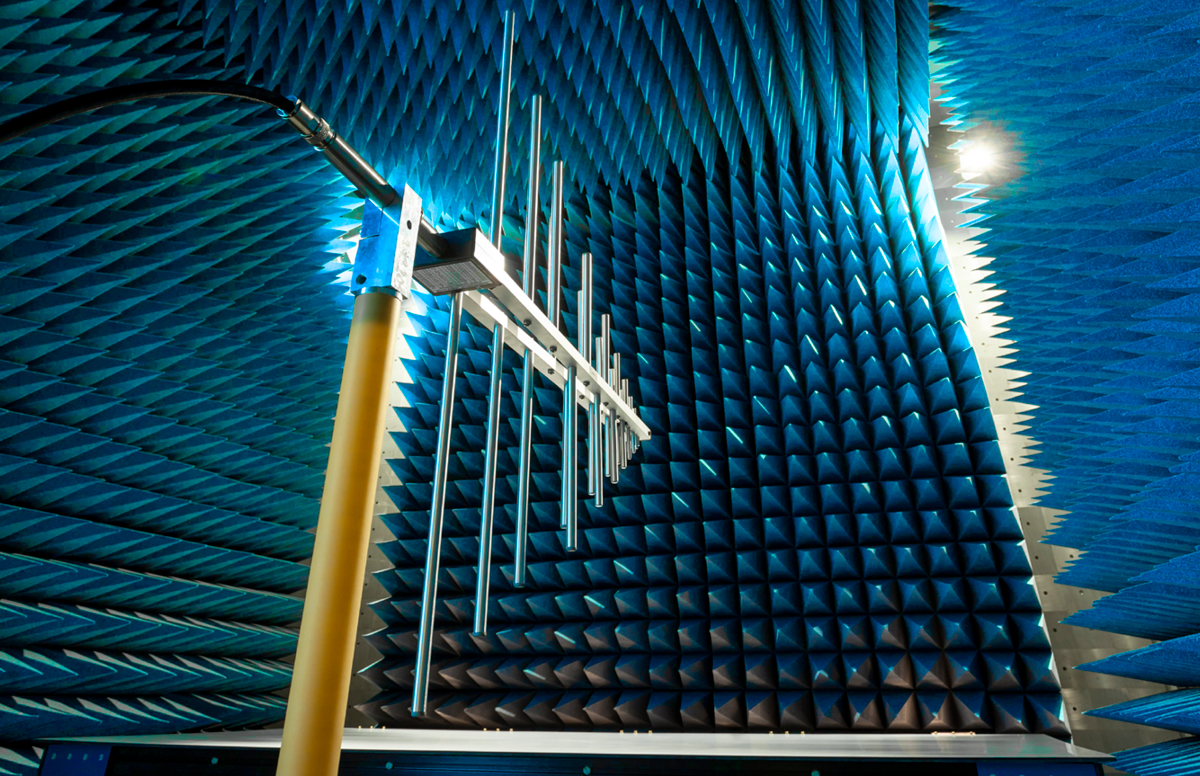

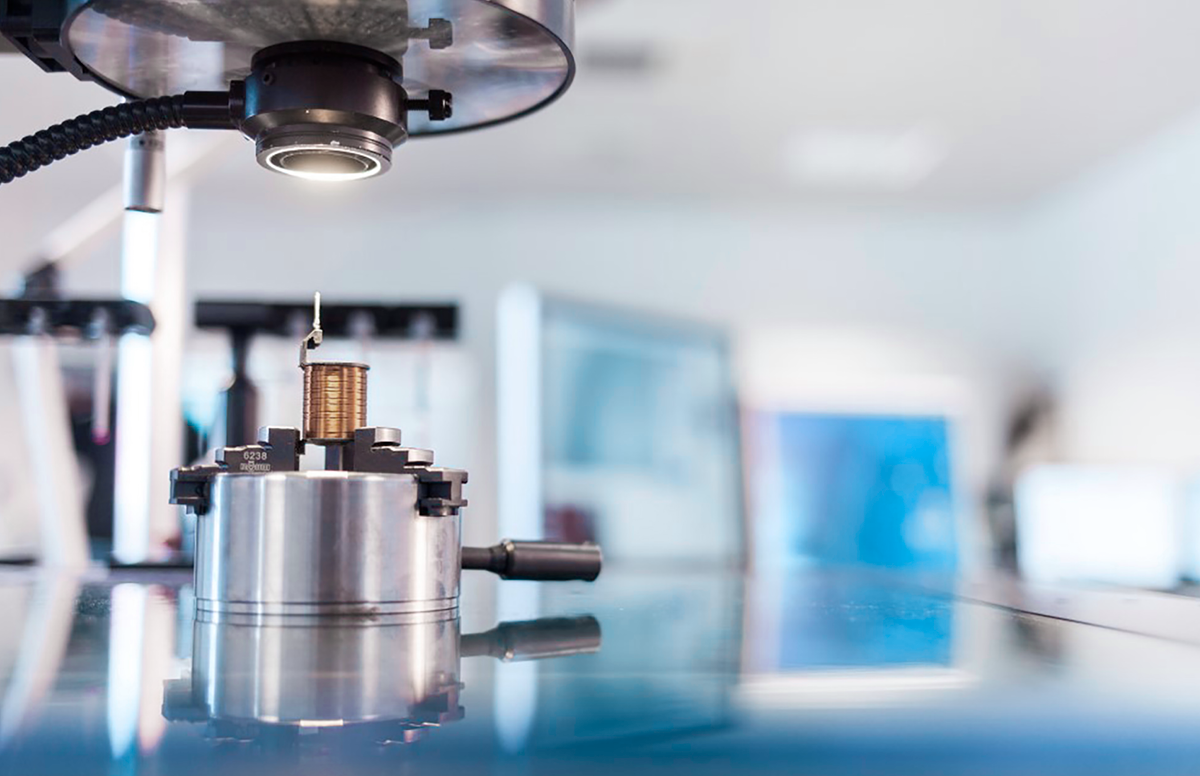

Laboratories

At Thomas, all product developments are subjected to an extensive analysis and testing program before they go into production. For this purpose, an analysis, a measurement technology and a test laboratory are available on a floorspace of more than 1,500 m². From the development of new products to the assurance of quality in the manufacturing process, the laboratory provides both metrological and methodical support in order to achieve maximum customer satisfaction. Our way of working is shaped by the Six Sigma methodology.

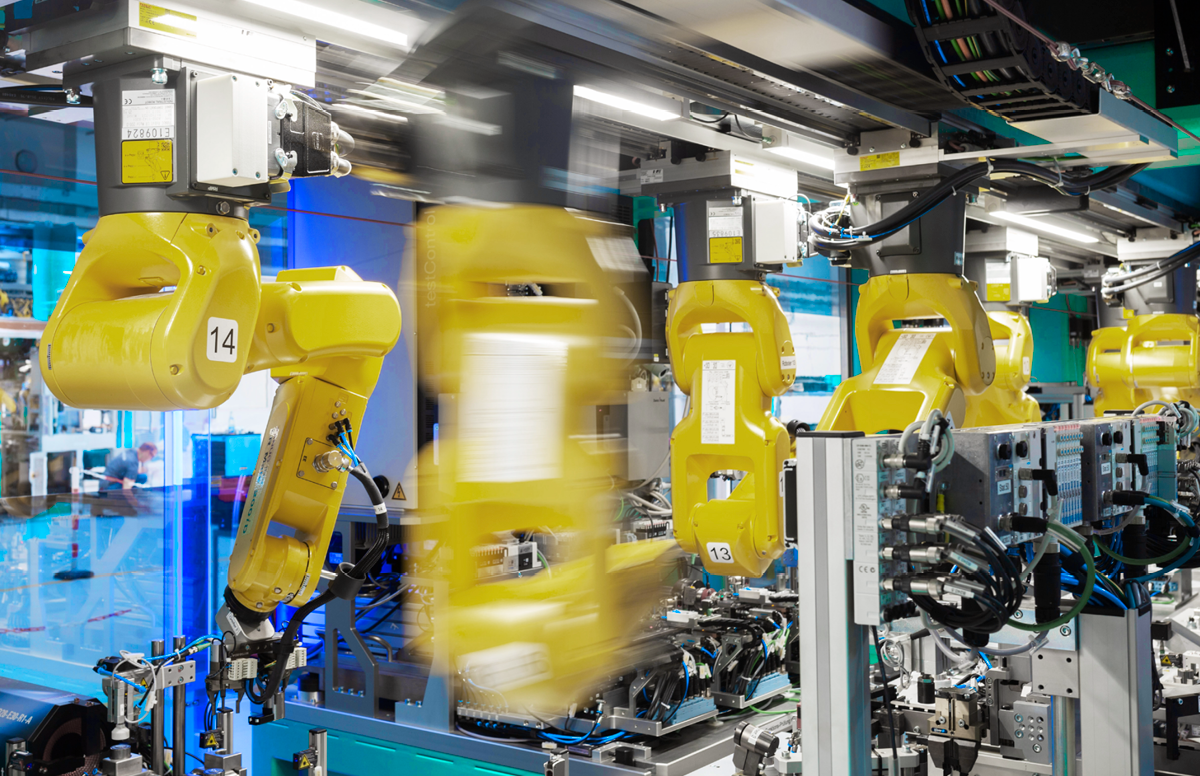

Manufacturing

Modular and scalable production according to Industry 4.0 standard. Integrated and simultaneous process and product development: fast set-up and flexibility in terms of product variants. Thanks to the ongoing expansion of automation with regard to manufacturing and control processes, we have seen continuous improvements in terms of quality, costs, and value.